Artificial Intelligence (AI) has made significant strides in various sectors, and its application in quality control is no exception. Companies are increasingly turning to AI technologies to enhance their quality assurance processes, reduce defects, and improve overall efficiency. This article delves into the latest trends, solutions, and industry applications of AI for quality control, with a focus on Amazon Web Services (AWS) AI and Jasper AI.

.

**The Growing Importance of Quality Control in Manufacturing**

Quality control (QC) is a critical component of manufacturing that ensures products meet specified standards and customer expectations. Traditional QC methods often involve manual inspections, which can be time-consuming and prone to human error. As industries strive for higher efficiency and lower costs, the integration of AI into quality control processes is becoming more prevalent.

.

**AI for Quality Control: Transforming Traditional Methods**

AI technologies such as machine learning and computer vision are transforming how quality control is conducted. Machine learning algorithms can analyze vast amounts of data to identify patterns and anomalies that may indicate defects. Computer vision systems can inspect products in real-time, ensuring that any imperfections are detected before items reach the consumer.

.

**Amazon Web Services (AWS) AI: A Game Changer for Quality Control**

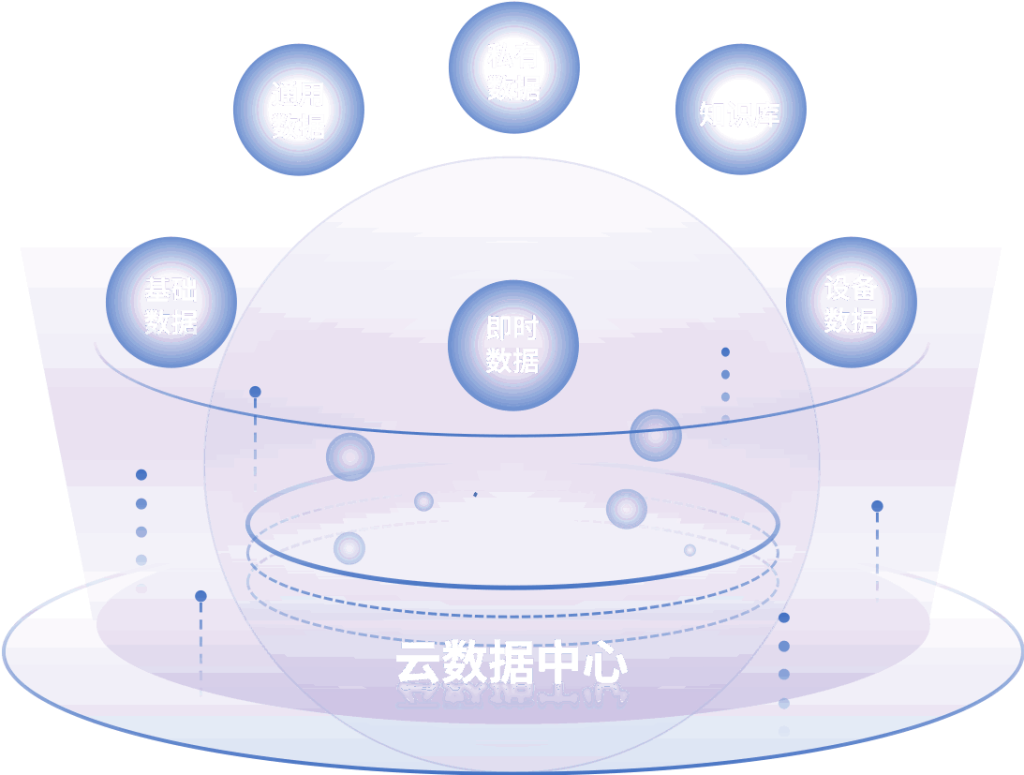

Amazon Web Services (AWS) offers a suite of AI tools that can be leveraged for quality control applications. AWS provides machine learning services like Amazon SageMaker, which allows businesses to build, train, and deploy machine learning models at scale. Companies can use these models to predict potential quality issues based on historical data, enabling proactive measures to mitigate risks.

.

AWS also offers Amazon Rekognition, a powerful image and video analysis service. This tool can be utilized in quality control to perform visual inspections of products, detecting defects or inconsistencies that may not be visible to the naked eye. By automating these inspections, companies can significantly reduce the time and labor costs associated with manual quality checks.

.

**Jasper AI: Enhancing Quality Control Processes**

Jasper AI is another innovative solution that is gaining traction in the realm of quality control. Jasper specializes in natural language processing (NLP) and can be used to analyze customer feedback, product reviews, and other textual data to identify quality-related issues. By understanding customer sentiments and concerns, businesses can address quality issues more effectively and enhance their products.

.

Jasper AI can also assist in the documentation process, ensuring that quality control reports are generated accurately and efficiently. By automating these tasks, companies can free up valuable resources and focus on more strategic initiatives.

.

**Industry Applications of AI for Quality Control**

Several industries are already reaping the benefits of AI-driven quality control solutions. In the automotive sector, manufacturers are using AI to monitor production lines and detect defects in real-time. This not only improves product quality but also reduces the risk of costly recalls.

.

In the food and beverage industry, AI-powered systems are being employed to ensure that products meet safety and quality standards. For example, machine learning algorithms can analyze data from sensors to detect anomalies in production processes, such as temperature fluctuations that could compromise food safety.

.

The pharmaceutical industry is also leveraging AI for quality control. By using AI to analyze data from clinical trials and production processes, companies can identify potential quality issues early on, ensuring that products are safe and effective before they reach the market.

.

**Technical Insights: How AI Works in Quality Control**

The integration of AI into quality control processes involves several technical components. Machine learning algorithms, for instance, require large datasets to train models effectively. These datasets often include historical quality control data, production metrics, and customer feedback.

.

Once the data is collected, it is pre-processed to remove noise and irrelevant information. This step is crucial for ensuring that the machine learning model can learn effectively. After pre-processing, the data is split into training and testing sets to evaluate the model’s performance.

.

Computer vision systems, on the other hand, rely on image recognition techniques to analyze visual data. These systems are trained using labeled images, where defects are annotated to help the model learn what to look for. Once trained, the system can analyze new images in real-time, providing immediate feedback on product quality.

.

**Challenges and Solutions in Implementing AI for Quality Control**

While the benefits of AI in quality control are clear, there are also challenges that organizations must navigate. One significant challenge is the integration of AI systems with existing processes and technologies. Many companies still rely on legacy systems, making it difficult to adopt AI solutions seamlessly.

.

To address this challenge, organizations can take a phased approach to implementation. Starting with pilot projects allows companies to test AI solutions on a smaller scale before rolling them out across the organization. This approach also provides valuable insights into the effectiveness of the AI system and any necessary adjustments.

.

Another challenge is the need for skilled personnel to manage and maintain AI systems. The demand for data scientists and AI specialists is growing, and companies may struggle to find qualified candidates. Investing in training and development programs for existing employees can help bridge this skills gap and ensure that organizations can effectively leverage AI technologies.

.

**The Future of AI in Quality Control**

As AI technologies continue to evolve, their applications in quality control are expected to expand further. The integration of advanced analytics, IoT devices, and AI will enable even more sophisticated quality control systems that can predict and prevent defects before they occur.

.

Moreover, the ongoing development of explainable AI (XAI) will enhance transparency in AI-driven quality control processes. By providing insights into how AI models make decisions, organizations can build trust in these systems and ensure compliance with regulatory standards.

.

**Conclusion: Embracing AI for Enhanced Quality Control**

The integration of AI into quality control processes represents a significant advancement for industries seeking to improve product quality and operational efficiency. With solutions like AWS AI and Jasper AI leading the charge, businesses can leverage the power of machine learning and natural language processing to enhance their quality assurance efforts.

.

As organizations continue to embrace AI technologies, the future of quality control looks promising. By overcoming challenges and investing in the right tools and talent, companies can position themselves for success in an increasingly competitive marketplace.

.

**Sources:**

1. Amazon Web Services. (n.d.). Amazon SageMaker. Retrieved from [AWS](https://aws.amazon.com/sagemaker/)

2. Amazon Web Services. (n.d.). Amazon Rekognition. Retrieved from [AWS](https://aws.amazon.com/rekognition/)

3. Jasper AI. (n.d.). Jasper AI Overview. Retrieved from [Jasper](https://www.jasper.ai/)

4. McKinsey & Company. (2021). The Future of Quality Control in Manufacturing. Retrieved from [McKinsey](https://www.mckinsey.com/industries/manufacturing/our-insights/the-future-of-quality-control-in-manufacturing)

5. Deloitte Insights. (2020). AI in Quality Control: Opportunities and Challenges. Retrieved from [Deloitte](https://www2.deloitte.com/us/en/insights/industry/manufacturing/ai-in-quality-control.html)