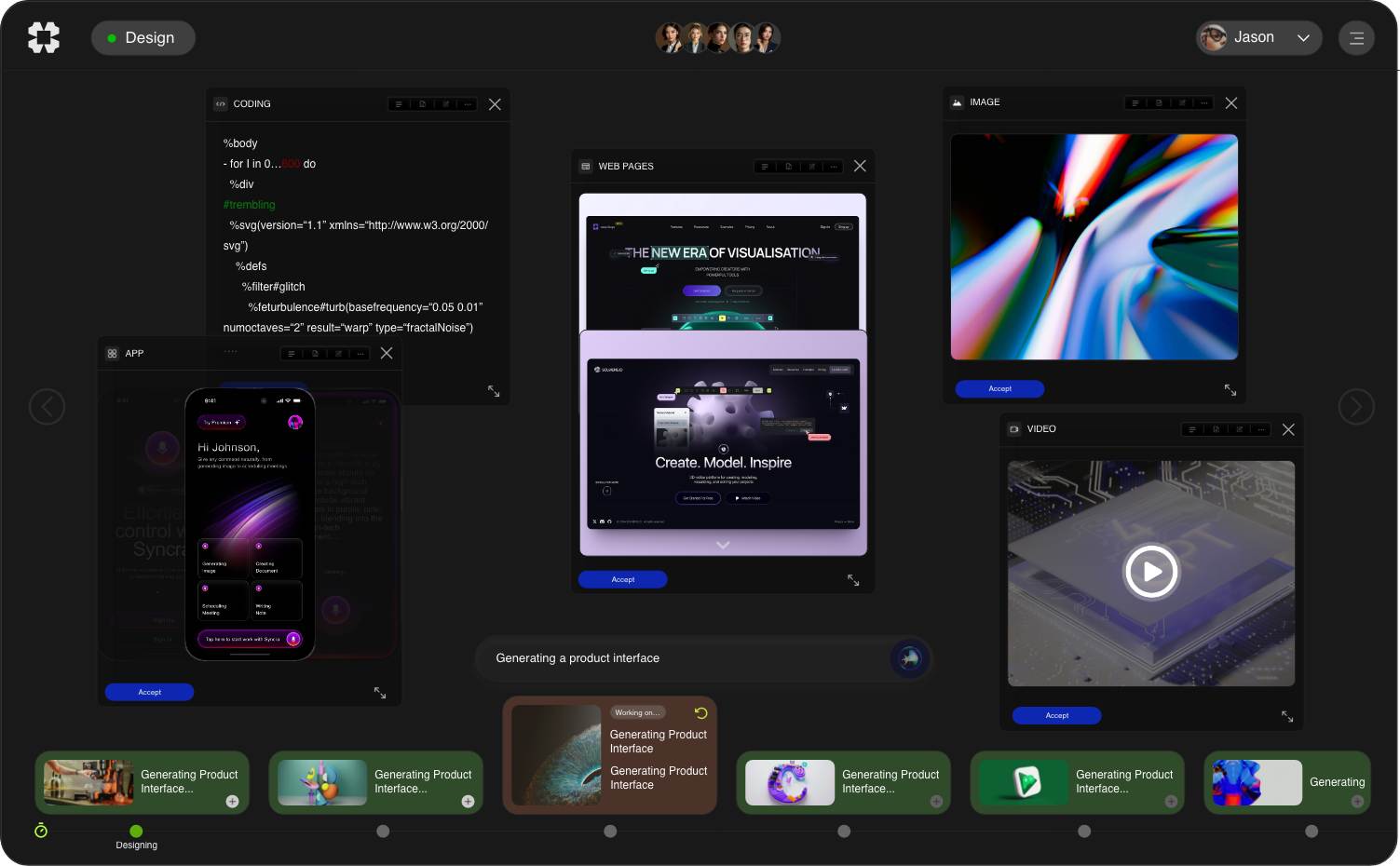

In recent years, the manufacturing landscape has undergone transformative changes fueled by advancements in artificial intelligence (AI) and automation technologies. As industries strive for efficiency, cost-effectiveness, and enhanced productivity, AI-driven task automation is emerging as a game-changer. This article delves into the trends, updates, and applications related to AI in smart manufacturing, highlighting how AI-driven operational insights are redefining the industry’s future.

.

## A New Era of Task Automation in Manufacturing

Task automation has historically been an integral part of manufacturing. However, with the introduction of AI, the level of sophistication in these systems has significantly advanced. Traditional automation followed scripted responses to machine commands, while AI-enabled tools can learn and adapt in real-time.

These innovative technologies utilize machine learning algorithms to analyze data from various sources, enhancing their ability to predict machine failures, optimize production schedules, and manage inventory efficiently. The convergence of AI and automation is giving rise to smart factories — environments characterized by interconnectivity, data exchange, and autonomous operation.

.

## Exploring AI in Smart Manufacturing

In the realm of smart manufacturing, AI is acting as a backbone for optimizing operations. AI technologies, such as predictive analytics and deep learning models, enable manufacturers to automate complex tasks that were once reliant on human oversight.

Consider AI’s role in predictive maintenance practices. By continuously monitoring equipment and analyzing historical data, AI systems can detect early warning signs of machine failure. This proactive approach helps manufacturers schedule maintenance during off-hours, significantly reducing downtime and saving costs. According to a report from McKinsey, predictive maintenance could reduce maintenance costs by 30% while avoiding equipment failure downtime by 70%.

The implementation of AI also extends to supply chain management, where AI-driven algorithms can provide real-time insights into inventory levels, forecast demand, and optimize resource allocation. The result is a more agile and responsive manufacturing process that can adapt quickly to ever-changing market conditions.

.

## The Significance of AI-Driven Operational Insights

At the core of task automation lies AI-driven operational insights, which enable organizations to extract significant value from the data they collect on the shop floor. Through advanced analytics, AI systems can deliver actionable insights that inform decision-making.

For example, AI can aggregate data from sensors embedded in production machinery alongside enterprise resource planning (ERP) systems to create a holistic view of operations. This fusion of data allows organizations to identify inefficiencies in real-time, drive process improvements, and enhance overall equipment effectiveness (OEE).

Furthermore, AI can uncover patterns and correlations that human analysts might overlook. Suppose an organization notices a recurring delay in production. An AI model might indicate that the issue stems from variations in raw material quality. Armed with this insight, the organization can work with suppliers to improve material consistency, thereby resolving the bottleneck effectively.

.

## Recent Trends and Innovations in AI Task Automation

As we look at the latest trends in AI-driven task automation, the rise of collaborative robots, or cobots, deserves special mention. Unlike traditional industrial robots, cobots are designed to work alongside human operators, enhancing productivity while allowing workers to focus on more complex tasks.

Additionally, companies are increasingly adopting digital twins, which are virtual representations of physical systems. These simulations can incorporate AI algorithms to predict outcomes and optimize workflows, enabling manufacturers to test processes before implementing changes in the physical environment.

A recent report from Deloitte indicates that 58% of manufacturers are investing in AI and machine learning. The report suggests that this trend will only grow, as companies begin to see significant returns on their investments in automation technologies, enhanced operational insights, and productivity improvements.

.

## Industry Applications and Use Cases

The potential of AI-driven task automation and operational insights is manifesting in various industries, driving meaningful changes to production methodologies.

1. **Automotive Manufacturing**: Leading automotive manufacturers like Tesla and Toyota utilize AI to automate assembly lines effectively. AI algorithms predict equipment malfunctions before they occur, ensuring machinery operates seamlessly. This predictive approach allows for holistic workflow improvement and a reduction in operational costs.

2. **Food and Beverage Industry**: AI-driven systems are playing a pivotal role in quality control and process optimization within this sector. By automating the inspection of products through computer vision, manufacturers can ensure that only quality products reach the market. Moreover, AI can help forecast demand accurately, reducing waste and ensuring optimal inventory levels.

3. **Pharmaceutical Manufacturing**: AI enhances drug production by automating tasks related to compliance, quality assurance, and supply chain management. Predictive analytics help in maintaining quality during production, ensuring adherence to regulatory standards.

4. **Electronics Manufacturing**: The electronics sector leverages AI for quality testing and assembly process optimization. By utilizing AI algorithms that can identify defects at a microscopic level, companies significantly enhance production quality and reduce recalls.

.

## Overcoming Challenges in AI-Driven Automation

While the advantages of AI in smart manufacturing are evident, several challenges remain that organizations must navigate. Data security is a primary concern, as sensitive information may be vulnerable to cyber threats. Manufacturers must prioritize cybersecurity protocols to ensure that data remains protected.

Additionally, the workforce remains a crucial consideration in the transition to AI-driven processes. There are fears regarding job displacement due to automation. However, a proactive approach to workforce development can mitigate such concerns. Upskilling existing employees through training programs on AI technologies can transition the workforce towards more strategic roles that emphasize decision-making and creativity.

.

## Future Outlook: Embracing Smart Manufacturing

As manufacturers continue to adopt AI in their operations, the future of smart manufacturing looks promising. Companies that strategically invest in AI-driven task automation will likely gain a competitive edge, reducing costs while enhancing quality and efficiency.

Moving forward, collaboration between organizations, technology providers, and academic institutions will be vital to drive innovation in AI applications in manufacturing. Continued research in AI algorithms, quantum computing, and big data analytics will further enhance operational insights.

Moreover, companies must cultivate a culture that embraces digital transformation. As they experiment and innovate, the expanded use of AI-driven insights, task automation, and collaborative technologies will pave the way for more flexible, productive, and competitive manufacturing environments.

.

In conclusion, AI-driven task automation and operational insights represent a seismic shift in the manufacturing industry. With the potential to transform how production is carried out, organizations must embrace these technologies, align them with their strategic goals, and tackle the associated challenges head-on. The journey towards smart manufacturing isn’t merely a trend—it’s the future of industry.

## Sources

1. McKinsey & Company. (2023). The Future of Manufacturing: Advances in Automation and AI.

2. Deloitte Insights. (2023). The Automation and AI Playbook for Manufacturers.

3. Fortune Business Insights. (2023). Smart Manufacturing Market Trends.

4. PwC. (2023). Industry 4.0: How AI is Changing Manufacturing.

5. Accenture. (2023). The Future of Smart Manufacturing: How AI is Driving Change.