In the rapidly evolving landscape of smart manufacturing, the integration of advanced technologies is transforming traditional production processes into highly efficient, adaptive systems. At the heart of this transformation are Smart Operating Systems (Smart OS) and Adaptive Operating Systems (AIOS), which leverage artificial intelligence to optimize operations, enhance productivity, and drive innovation. This article explores the latest trends, solutions, and applications of these technologies in the manufacturing sector, highlighting their impact on industry practices and future prospects.

.

### Understanding Smart OS and Adaptive Operating Systems

Smart OS refers to operating systems designed to support the complex needs of modern manufacturing environments. These systems are equipped with advanced features that allow for real-time data processing, machine learning, and seamless integration with IoT devices. On the other hand, Adaptive Operating Systems (AIOS) take this a step further by utilizing artificial intelligence to learn from data patterns, adapt to changes in the manufacturing process, and optimize performance dynamically.

.

The convergence of Smart OS and AIOS is pivotal in creating a more responsive manufacturing environment. By harnessing data from various sources, including machines, sensors, and supply chains, these systems can make informed decisions that enhance operational efficiency. This adaptability is crucial in an era where consumer demands are constantly changing, and manufacturers must remain agile to stay competitive.

.

### Current Trends in Smart Manufacturing

The adoption of Smart OS and AIOS is driven by several key trends in the manufacturing industry. One of the most significant is the increasing reliance on data analytics. Manufacturers are now collecting vast amounts of data from their operations, and Smart OS are equipped to analyze this data in real-time. This capability allows for predictive maintenance, where potential equipment failures can be identified before they occur, significantly reducing downtime and repair costs.

.

Another trend is the growing importance of sustainability in manufacturing. Smart OS can optimize resource usage, minimize waste, and reduce energy consumption. By analyzing production processes, these systems can identify inefficiencies and suggest improvements, aligning with global sustainability goals. For instance, manufacturers can implement energy-efficient practices that not only lower costs but also enhance their corporate responsibility profile.

.

### Solutions Offered by Smart OS and AIOS

Smart OS and AIOS provide a range of solutions that address the challenges faced by modern manufacturers. One of the most notable solutions is the implementation of digital twins. A digital twin is a virtual representation of a physical object or system, allowing manufacturers to simulate and analyze performance in real-time. By integrating Smart OS with digital twin technology, manufacturers can optimize production processes, test new strategies, and predict outcomes without disrupting actual operations.

.

Moreover, these operating systems facilitate enhanced collaboration across the supply chain. With the ability to connect various stakeholders, from suppliers to distributors, Smart OS can streamline communication and improve coordination. This interconnectedness ensures that all parties are aligned, reducing lead times and enhancing overall efficiency.

.

### Industry Applications of Smart OS and AIOS

The applications of Smart OS and AIOS in manufacturing are vast and varied. In the automotive industry, for example, manufacturers are using these systems to enhance assembly line efficiency. By analyzing data from various stages of production, AIOS can identify bottlenecks and suggest adjustments in real-time, ensuring a smoother workflow.

.

In the electronics sector, Smart OS are being utilized to manage complex supply chains. With the rapid pace of technological advancement, manufacturers must adapt quickly to changes in demand. Smart OS can analyze market trends and consumer behavior, allowing companies to adjust their production schedules accordingly, thus minimizing excess inventory and reducing costs.

.

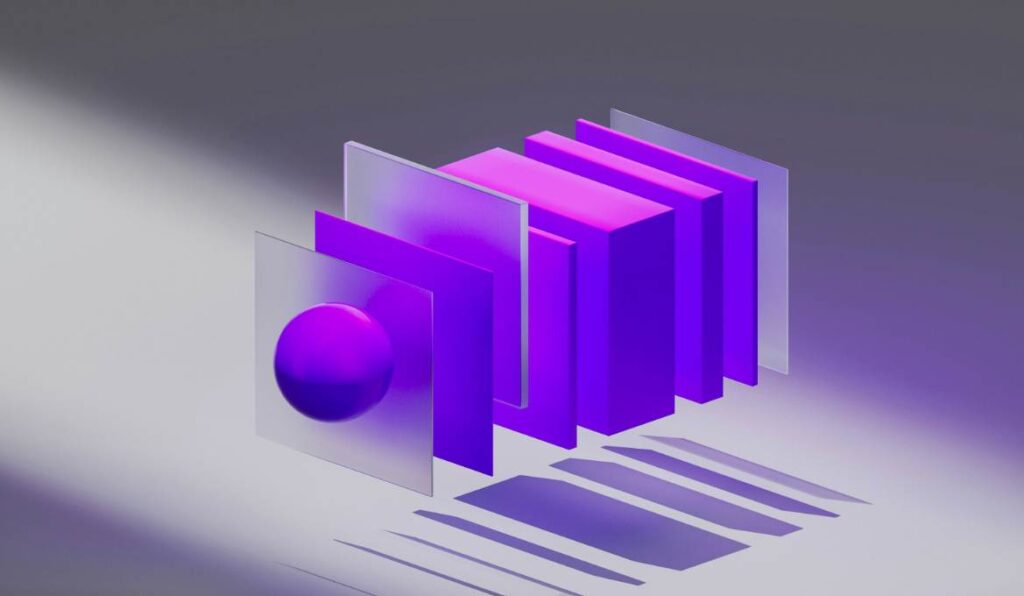

### Technical Insights: The Architecture of Smart OS and AIOS

The architecture of Smart OS and AIOS is critical to their functionality. These systems typically consist of several layers, including data acquisition, data processing, and application layers. At the data acquisition layer, IoT devices and sensors collect real-time data from machines and production processes. This data is then transmitted to the processing layer, where advanced algorithms analyze it to extract meaningful insights.

.

The application layer is where the real power of Smart OS and AIOS is realized. Here, manufacturers can implement various applications, such as predictive maintenance tools, production optimization software, and supply chain management systems. The integration of machine learning algorithms allows these applications to continuously improve over time, adapting to new data and changing conditions.

.

### Case Studies: Success Stories in Smart Manufacturing

Several companies have successfully implemented Smart OS and AIOS, showcasing the transformative potential of these technologies. For instance, Siemens has integrated AIOS in its Amberg Electronics Plant, where it utilizes real-time data to optimize production processes. The result has been a significant increase in efficiency, with production times reduced by over 50%.

.

Similarly, General Electric (GE) has embraced Smart OS in its manufacturing facilities. By leveraging data analytics and machine learning, GE has improved its predictive maintenance capabilities, leading to a reduction in unplanned downtime and substantial cost savings. These success stories illustrate how Smart OS and AIOS are not just theoretical concepts but practical solutions that deliver tangible results.

.

### Challenges and Future Directions

Despite the numerous benefits, the implementation of Smart OS and AIOS is not without challenges. One of the primary concerns is data security. As manufacturers increasingly rely on interconnected systems, the risk of cyberattacks grows. Ensuring robust cybersecurity measures is essential to protect sensitive data and maintain operational integrity.

.

Additionally, the transition to Smart OS and AIOS requires significant investment in technology and training. Manufacturers must be willing to invest in new infrastructure and upskill their workforce to fully leverage these advanced systems. However, the long-term benefits, including increased efficiency and reduced costs, often outweigh the initial challenges.

.

Looking ahead, the future of Smart OS and AIOS in manufacturing appears bright. As technology continues to evolve, these systems will become even more sophisticated, incorporating advancements in machine learning, edge computing, and blockchain technology. The potential for enhanced automation, improved decision-making, and greater sustainability will drive further adoption across the industry.

.

### Conclusion

The rise of Smart OS and Adaptive Operating Systems in smart manufacturing represents a paradigm shift in how production processes are managed. By leveraging real-time data, AI, and advanced analytics, manufacturers can optimize operations, enhance productivity, and respond swiftly to changing market demands. As the industry continues to evolve, embracing these technologies will be crucial for manufacturers seeking to remain competitive in an increasingly complex landscape.

.

In conclusion, the integration of Smart OS and AIOS is not merely a trend; it is a fundamental transformation that will shape the future of manufacturing. As companies navigate the challenges and opportunities presented by these technologies, the potential for innovation and growth is limitless.

**Sources:**

1. Siemens AG. (2021). “Digitalization in Manufacturing: The Future of Production.” Retrieved from [Siemens](https://www.siemens.com/global/en/company/topic-areas/digitalization.html).

2. General Electric. (2020). “How GE is Using AI to Transform Manufacturing.” Retrieved from [GE Reports](https://www.ge.com/reports/).

3. McKinsey & Company. (2022). “The Future of Manufacturing: Smart Technologies and Industry 4.0.” Retrieved from [McKinsey](https://www.mckinsey.com/industries/manufacturing/our-insights).

4. Deloitte Insights. (2021). “The Smart Factory: How AI and IoT are Transforming Manufacturing.” Retrieved from [Deloitte](https://www2.deloitte.com/us/en/insights/industry/manufacturing/smart-factory.html).