In a world where technology interlaces with daily existence, the advent of Artificial Intelligence (AI) has notably altered operational paradigms across various sectors. The emergence of AI-enhanced Operating Systems (AIOS) is a prime example of this exceptional technological advancement. Companies are scrambling to leverage the potential of AIOS in smart manufacturing arenas, with implications that could reshape the fabric of industrial operations. .

**Understanding AIOS Automation**

At the crux of this transformation lies AIOS Automation, which combines traditional operating systems with intellig ent algorithms to enhance efficiency and productivity. An AIOS integrates machine learning, data analytics, and real-time feedback, allowing for agile response to fluctuations within manufacturing environments. This innovation empowers manufacturers to analyze vast datasets in a timely manner, fostering smarter decision-making and automating mundane tasks. .

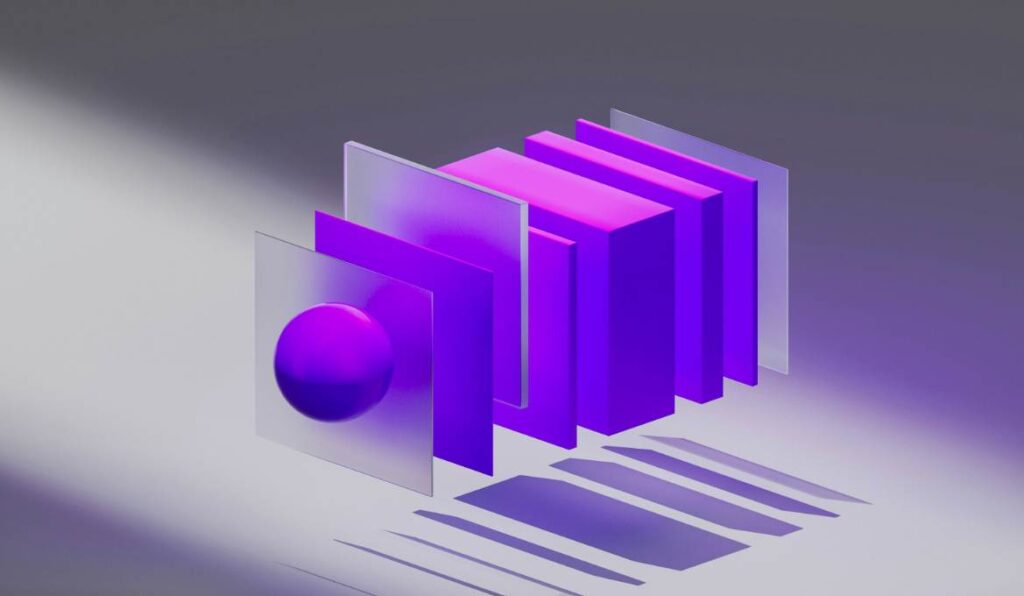

AIOS technology operates on layers of abstraction that condense complex information and present it meaningfully to operators. By analyzing historical performance data, AIOS can predict machine failures, schedule maintenance, and optimize production schedules. These capabilities illustrate AIOS’s promise in elevating manufacturing processes to a new standard. .

**Trends in AIOS for Smart Manufacturing**

As industries adopt AIOS, several trends emerge that underscore its significance in smart manufacturing. One notable trend is the growing collaboration between AI models and human operators. Unlike traditional automation methods that seek to replace human intervention, AIOS systems are designed to work symbiotically with humans, enhancing their capabilities rather than supplanting them. This complementary dynamic leads to improved operational accuracy and safety across plants. .

Another trend involves the rise of predictive maintenance. Traditional maintenance strategies can be costly and inefficient, often leading to unexpected downtimes. AI-powered systems equipped with machine learning can forecast equipment malfunctions before they occur. As a result, manufacturers are investing in AIOS to harness predictive algorithms that continuously analyze machine data and suggest proactive measures—ultimately reducing downtime and maintenance costs. .

Moreover, sustainable practices are on the rise thanks to AIOS innovations in energy management. AI-enhanced systems optimize energy usage in manufacturing plants, leading to reduced carbon footprints. These systems can analyze real-time energy consumption patterns, make adjustments, and even suggest alternative resources based on availability, cost, and environmental impact. Manufacturers embracing AIOS are not only improving their efficiency but also aligning with sustainability goals crucial for future competitiveness. .

**Technical Insights into AIOS**

The technical architecture of an AIOS plays a pivotal role in its effectiveness in smart manufacturing. At its core, an AIOS leverages a blend of edge computing and cloud computing capabilities. Edge computing allows for real-time data processing close to the machine, enabling prompt response to any changes on the shop floor. This infrastructure minimizes latency, enhancing the operational agility crucial for modern manufacturing environments. .

On the other hand, cloud computing facilitates extensive data storage and advanced analytics, empowering AI models to learn from accumulated data over time. By connecting disparate systems and machines to a centralized cloud platform, manufacturers can derive insights that drive smarter strategies. The seamless integration between edge and cloud computing fosters a robust AIOS capable of managing complex manufacturing ecosystems. .

Moreover, the concept of Digital Twins is another significant technical insight related to AIOS Automation. A digital twin is a virtual replica of a physical system that incorporates real-time data feeds, simulation capabilities, and predictive analytics. By adopting AI-enhanced OS in conjunction with digital twin technology, manufacturers can simulate constraints, forecast outcomes, and optimize processes before implementing any physical changes on the production line. This results not only in efficiency gains but also in considerable cost savings. .

**Industry Use Cases: AIOS in Action**

Numerous industries have successfully integrated AIOS Automation to reshape their manufacturing processes. For instance, in the automotive sector, companies like Ford and General Motors use AI-enhanced operating systems to streamline assembly lines. By employing AIOS, these companies can foresee potential bottlenecks in production and suggest optimal resource allocation. This agility is particularly crucial in an industry characterized by changing consumer demands and stringent regulations. .

In the electronics manufacturing space, AIOS has significantly improved quality assurance processes. Companies like Intel deploy AI-driven systems to analyze and inspect components during production. By using machine learning algorithms to identify patterns in defect data, manufacturers are better positioned to enhance product quality and decrease waste. This not only bolsters customer satisfaction but also reinforces brand integrity. .

Moreover, in the food and beverage industry, organizations are leveraging AIOS to enhance supply chain transparency and efficiency. For instance, Coca-Cola employs AI-enhanced operating systems to manage inventory and distribution more effectively. By analyzing real-time sales data, weather patterns, and supply chain dynamics, Coca-Cola can optimize its production schedules and minimize spoilage. This holistic approach allows for a more resilient supply chain that can swiftly respond to market changes. .

**Conclusion: Towards a Smarter Future with AIOS Automation**

As the landscape of smart manufacturing evolves, AIOS Automation stands at the forefront, reshaping how industries operate. With its ability to enhance efficiencies, decrease costs, and improve sustainability, the potential applications of AI-enhanced operating systems are boundless. .

Companies must remain committed to embracing these revolutionary technologies, as those who fail to adapt risk obsolescence in an increasingly competitive environment. The merger of AI with manufacturing processes not only promises enhanced productivity but a fundamental transformation—ushering in an era where intelligent systems and human expertise coalesce harmoniously. .

For those interested in keeping abreast of the advancements in AIOS, resources such as the National Institute of Standards and Technology (NIST), industry reports from McKinsey, and publications from the International Journal of Production Research provide valuable insights and case studies relevant to these technologies. As AIOS in smart manufacturing continues to develop, staying informed will be key to harnessing its full potential for future innovation. .