In today’s fast-paced business environment, the need for efficiency and adaptability drives organizations towards integrating smart technologies in their operations. One of the most profound transformations is the rise of Task Automation, specifically within the supply chain sector, where Artificial Intelligence (AI) plays a pivotal role in optimizing processes and enhancing decision-making. This article delves into how AI-driven solutions are reshaping supply chain management, exploring trends, applications, technical insights, and industry use cases.

The traditional supply chain model relies heavily on manual processes that often lead to inefficiencies, errors, and delays. The introduction of AI and task automation technologies provides organizations with the ability to streamline operations, minimize human intervention, and create a more agile supply chain environment. By automating repetitive tasks, such as inventory management, order processing, and demand forecasting, companies can redeploy human resources to focus on strategic activities that drive growth and innovation.

One of the most significant advancements in AI for Supply Chain Optimization is the development of predictive analytics tools. These tools utilize machine learning algorithms to analyze historical data, identify patterns, and forecast demand with unprecedented accuracy. Companies like Amazon and Walmart have successfully implemented such systems, allowing them to optimize stock levels, reduce waste, and enhance customer satisfaction. According to a report from MarketsandMarkets, the global supply chain analytics market is projected to grow from $3.8 billion in 2021 to $8.4 billion by 2026, highlighting the increasing importance of AI-driven analytics in supply chain operations.

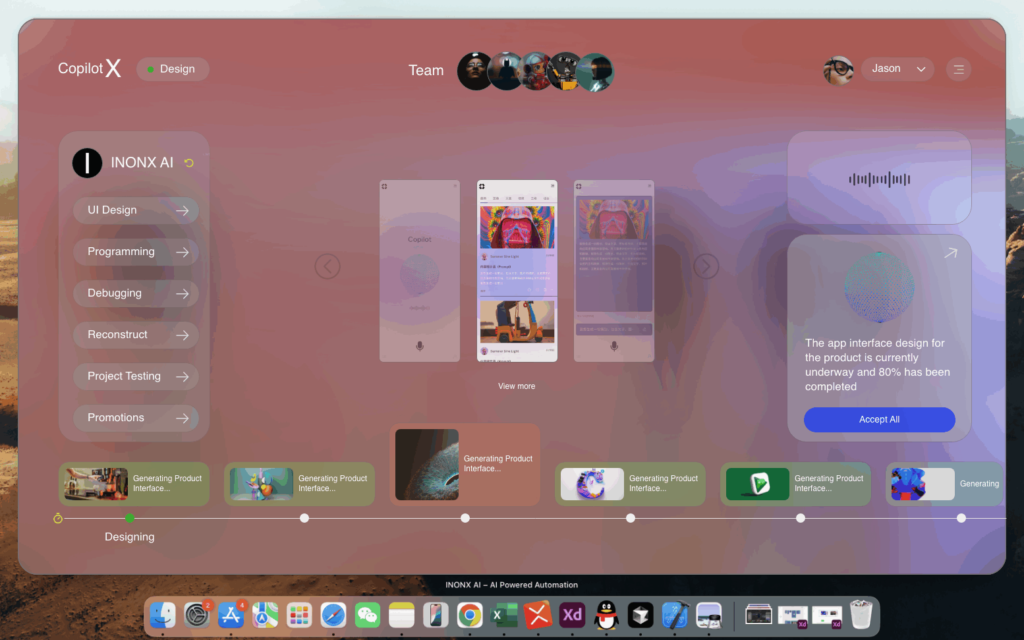

The integration of AI not only enhances efficiency but also offers the potential for real-time insights and improved decision-making. With AI-driven process management solutions, organizations can harness data from various sources, such as IoT devices, ERP systems, and social media platforms, to gain a comprehensive view of their supply chain. This data-driven approach enables faster response times and better risk management, an essential feature in an unpredictable global market.

AI-driven process management can also significantly enhance supplier and vendor relationships. By automating communication channels and employing natural language processing (NLP) to analyze interactions, companies can identify potential issues early and ensure smoother collaboration. This capability reduces delays and fosters a proactive rather than reactive approach in handling supply chain challenges. For instance, companies like Johnson & Johnson have employed AI to streamline their supplier communications, resulting in improved collaboration and a greater ability to adapt to changing market conditions.

Furthermore, task automation empowers organizations to maintain compliance with industry regulations more effectively. By automating documentation, record-keeping, and reporting processes, businesses can minimize the risk of human error while ensuring compliance with local and international standards. A study by Deloitte found that organizations leveraging AI for process automation achieved compliance accuracy improvements of over 30%, reducing the likelihood of costly fines and penalties.

As AI continues to mature, the adoption of robotic process automation (RPA) is becoming increasingly prevalent in supply chain management. RPA can mimic human actions to automate mundane tasks across various applications, such as data entry, invoice processing, and shipment tracking. The benefits of RPA are evidenced by companies like Unilever, which reported a significant reduction in processing times and a substantial increase in operational efficiency after implementing RPA within their supply chain operations.

**Trends and Solutions in AI-Driven Supply Chain Optimization**

With the growing reliance on AI for supply chain optimization, several trends are shaping the future of task automation within the industry. One notable trend is the expansion of AI-powered digital twins. Digital twins are virtual replicas of physical assets and processes, enabling companies to model and simulate scenarios for informed decision-making. By utilizing digital twins, organizations can optimize inventory levels, predict maintenance needs, and streamline production processes in real-time.

Moreover, the rise of AI-enabled demand forecasting systems is transforming how companies plan their inventory. These systems are designed to analyze vast datasets and adapt to changing market conditions rapidly. As a result, organizations can better align their supply chain strategies with consumer demand, helping to avoid stockouts or overstock situations. For example, Zara has successfully implemented AI-driven demand forecasting tools to ensure their inventory is aligned with rapidly changing fashion trends, thus enhancing their responsiveness to customers.

The trend toward hyperautomation is another key focus area for organizations looking to streamline their supply chain processes. Hyperautomation combines task automation with advanced AI technologies to create a fully automated ecosystem where processes are self-optimizing and adaptable. By leveraging technologies like AI, machine learning, and RPA, organizations can increase efficiency, minimize operational risks, and drive innovation.

**Industry Applications and Technical Insights**

In various sectors, AI-driven task automation is yielding significant benefits. In the manufacturing industry, automation technologies enable the seamless management of complex supply chains. For instance, in automotive manufacturing, AI systems can analyze incoming parts data, monitor production schedules, and optimize assembly lines to minimize idle time and reduce production costs.

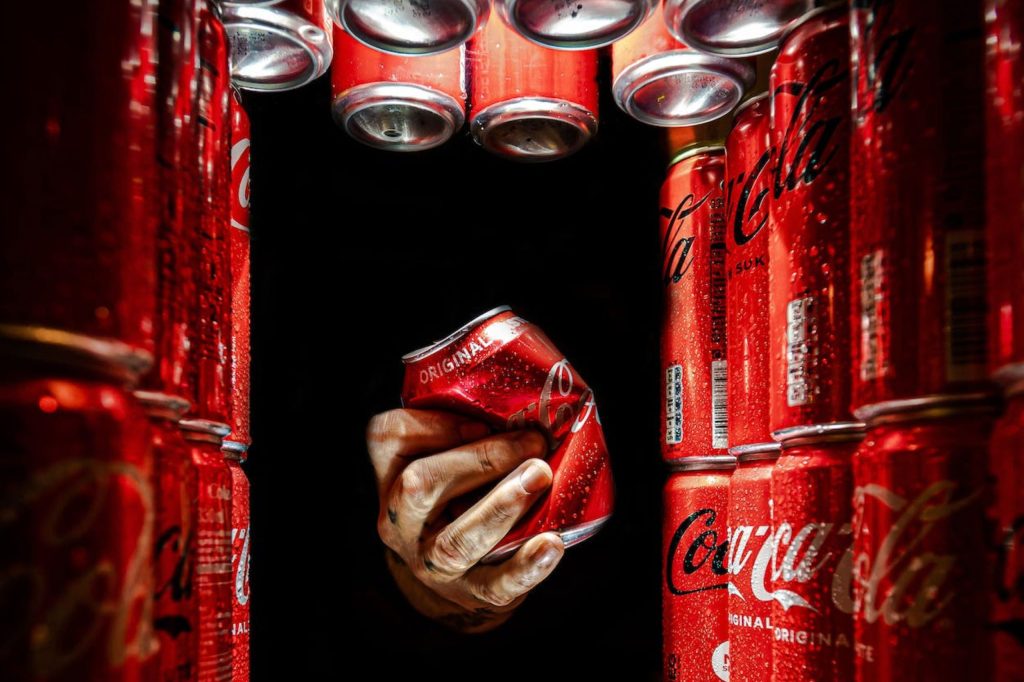

In the food and beverage sector, AI is transforming distribution and logistics. Companies are using AI algorithms to optimize delivery routes, track shipments in real-time, and manage shelf-life predictions for perishable goods. By implementing these technologies, companies can reduce food waste and ensure that products reach consumers while still fresh.

Technical insights into AI-driven task automation also reveal significant opportunities for improvement. Many companies are increasingly adopting cloud-based AI solutions for enhanced scalability and flexibility. Cloud technologies allow organizations to analyze vast datasets and run complex algorithms without heavy investments in physical infrastructure. For instance, Google Cloud offers various AI tools that can analyze supply chain operations, creating actionable insights to optimize processes.

Additionally, the use of AI and machine learning in supply chain analytics is paving the way for predictive maintenance analysis. By monitoring equipment performance and analyzing historical data, algorithms can predict when machinery is likely to fail, enabling preemptive maintenance actions and minimizing downtime. This predictive approach not only enhances operational efficiency but also improves safety standards, significantly reducing the likelihood of workplace accidents.

**Industry Use Case: AI-Driven Task Automation in Action**

One prominent use case of AI-driven task automation is seen in the logistics sector with FedEx and its use of AI for operational efficiency. FedEx leverages advanced machine learning algorithms to analyze shipping data and optimize its delivery network. By predicting potential delays and re-routing packages in real-time, FedEx can maintain reliable service levels and increase customer satisfaction. The implementation of AI systems for task automation has led to reduced operational costs and significant improvements in on-time delivery performance.

Another case is the global beverage company Diageo, which employs AI-driven tools for yield optimization and supply chain management. By automating data collection and analysis processes, Diageo can predict production outcomes more accurately and identify areas for improvement. This data-driven approach enables the company to manage supply chain risks effectively and support sustainability initiatives by minimizing waste across operations.

**Conclusion: The Future of AI in Supply Chain Task Automation**

As the demand for efficiency and innovation grows, task automation in the realm of supply chain optimization will undoubtedly continue to expand. With AI technologies pushing the boundaries of what is possible, organizations that harness these advancements can achieve greater operational efficiency, reduce costs, and enhance customer satisfaction. From predictive analytics to robotic process automation, businesses must embrace these changes to remain competitive in an increasingly dynamic marketplace.

AI-driven task automation has become a necessity in the modern supply chain landscape. The benefits of streamlining processes, reducing human error, and improving decision-making capabilities are undeniable. Companies that adapt and implement these technologies will not only overcome current challenges but will also set themselves up for long-term success in an ever-evolving industry. The evolution of task automation in supply chains represents a significant shift, paving the way for a smarter, more resilient economy.